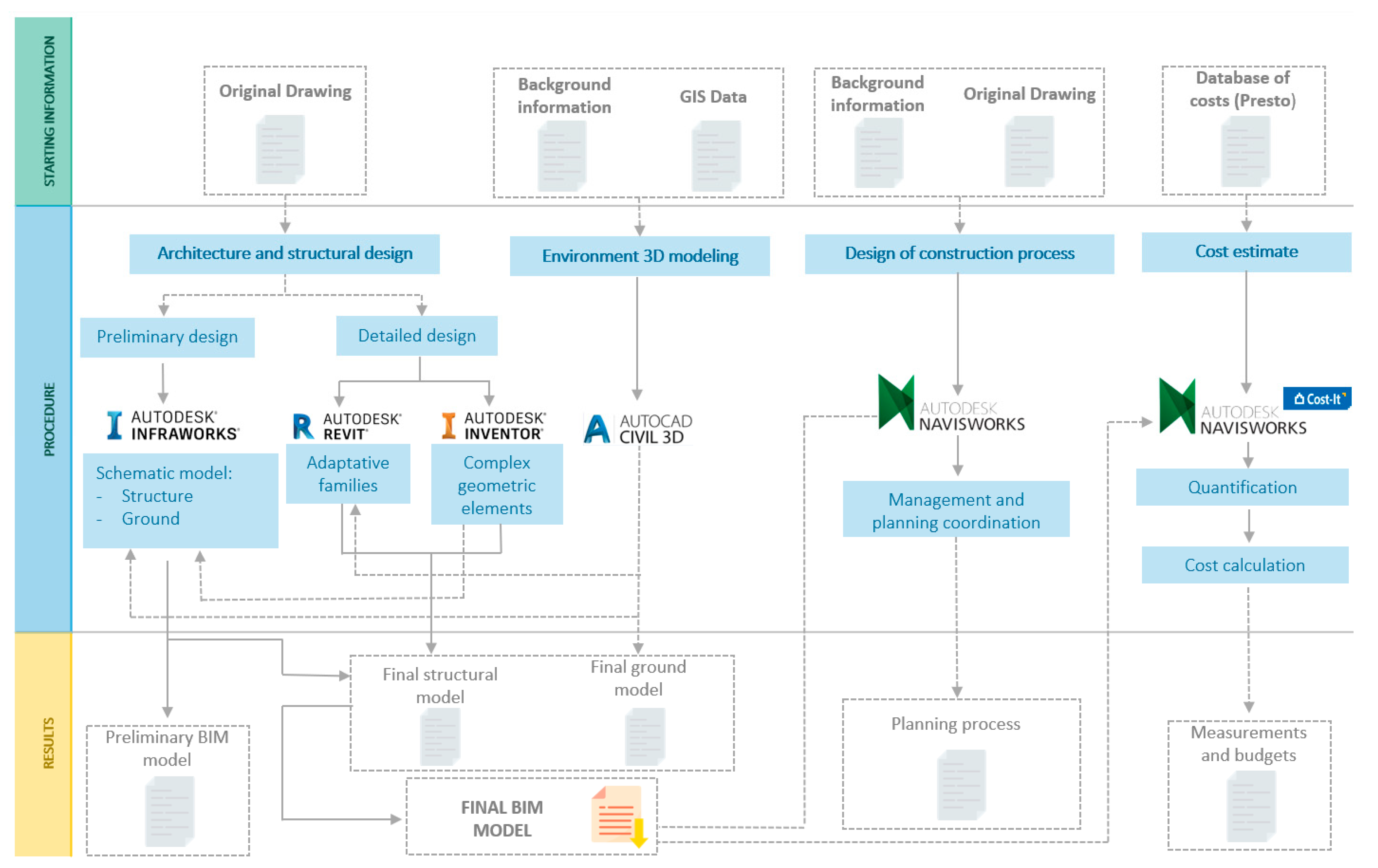

The first two are containers or jewelry boxes of sorts - part of a series of explorations I’m doing called the ‘Geode’ series which looks at the relationship between interior and exterior, continuous surface and texture. You should also check out this instructable on learning CNC in general!Īs examples, I’ll go through 3 separate projects, created in various 3D modeling programs, brought into Inventor Pro through various means and all programmed in HSM. This instructable assumes you have a design 3D modelled and have received training for a CNC machine of some sort and simply want to know how to go about programming your parts for machining. What follows is just that – a BASIC outline or general how-to for taking your design from any software to CAM and getting it ready for machining!

įor some of my colleagues here at the Pier as well as for many others, a basic outline for taking designs from the computer to whatever machine you want to use could be a helpful tool in the digital workflow.

However, I now have the opportunity to use some great tools and software at Autodesk Pier 9. CAM software seems to be the weak link in what could be a fluid streamlined process, but instead can be frustrating and difficult.Īdmittedly, I’m no expert in CAM software and until recently, the last time I used CAM for CNC routing some furniture pieces was almost 10 years ago. Of those, I’d be willing to bet even fewer still who have access to and are proficient at good CAM software. Out of those people, there are probably fewer who happen to have access to some sort of CNC machine (a ShopBot or other CNC router or mill). Many of you reading this probably have access to and experience with some sort of 3D design software whether it’s professional or free.

0 kommentar(er)

0 kommentar(er)